07/18/2025

Two-way communication with machinery

Agriculture 4.0 – a marriage of precision agriculture with digital technologies, has recently been discussed intensively, in particular in connection with the first edition of the funding programme in this area , targeting farms. The programme is supported from the National Recovery and Resilience Plan. In this busy period, the SatAgro team associates “Agriculture 4.0” above all with the ‘two-way wireless communication’ – by now quite a famous term among Polish farmers, about which we receive hundreds of enquiries. It’s first component, ‘The first direction’, is the transmission of instructions, primarily agrochemical application maps, from the Farm Management System (FMS, e.g. SatAgro) to the machine. ‘The second direction’ is the transfer of data from the machine to the FMS, primarily reports on the actual application rate executed based on the uploaded application map. Yield maps, fuel consumption, machine speed, and many other parameters of machinery operation can also be transmitted, often in the form of maps.

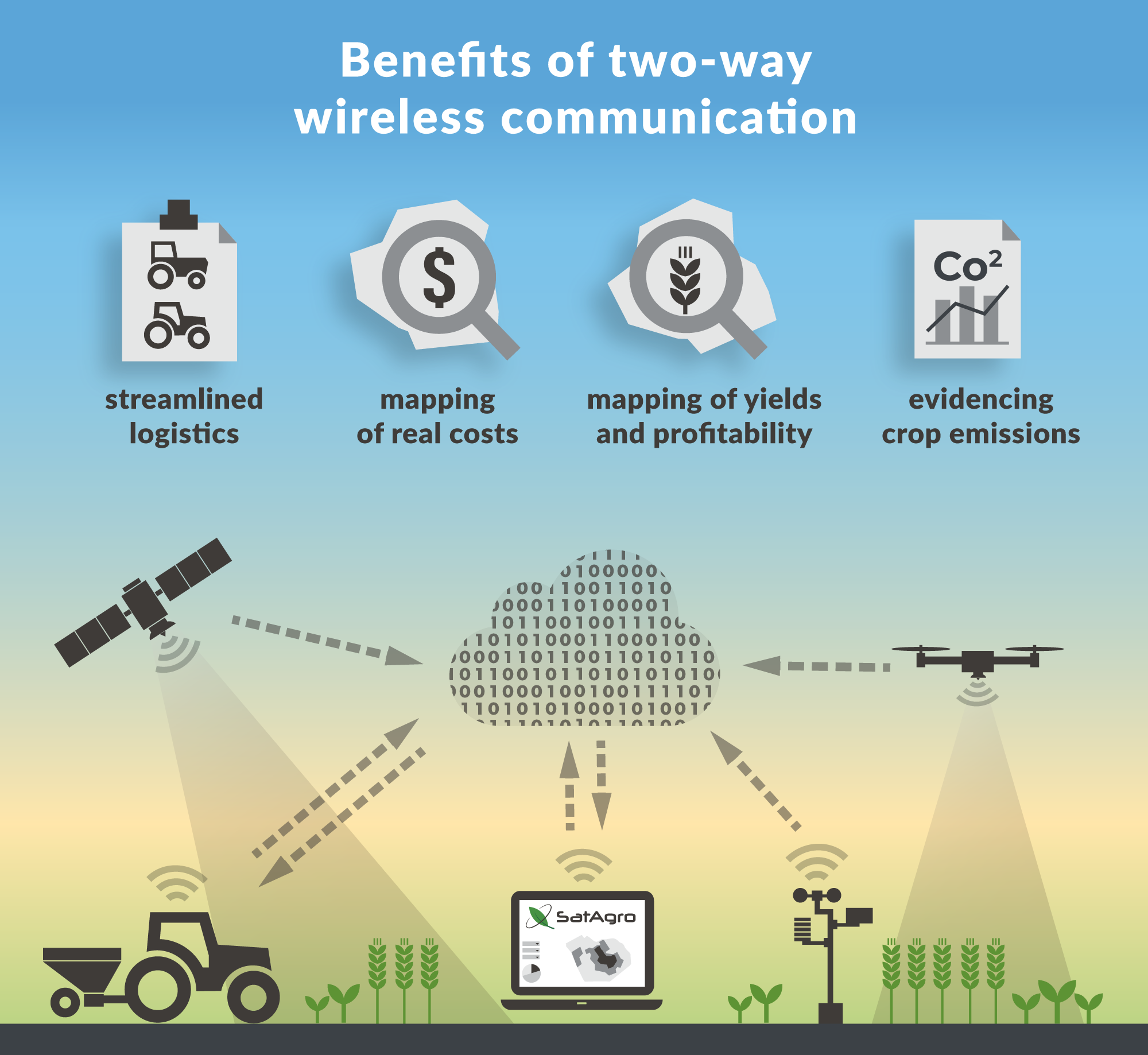

The benefits of communication

The transfer of application maps to agricultural machinery has always been one of SatAgro’s core functionalities, as it is the basis for crop optimisation. Nowadays, we are all swiftly entering a new phase, in which the “second direction” is gaining importance and machinery is beginning to communicate with us on a regular basis. Harnessing this communication opens up new possibilities for both increasing crop profitability and reducing its environmental impact.

The first benefit, which is the most general and probably also the most important, is the improvement of cultivation logistics, particularly with regard to the use of machinery. This is particularly true on larger farms, where there are so many workers and machines that documenting agro-technical treatments and related work is a challenge, even in terms of such basic parameters as execution time, crop area covered, route, application rate and fuel consumption. Often, the desire to control and optimise these basic aspects of logistics is the main motivation for a farm to go digital.

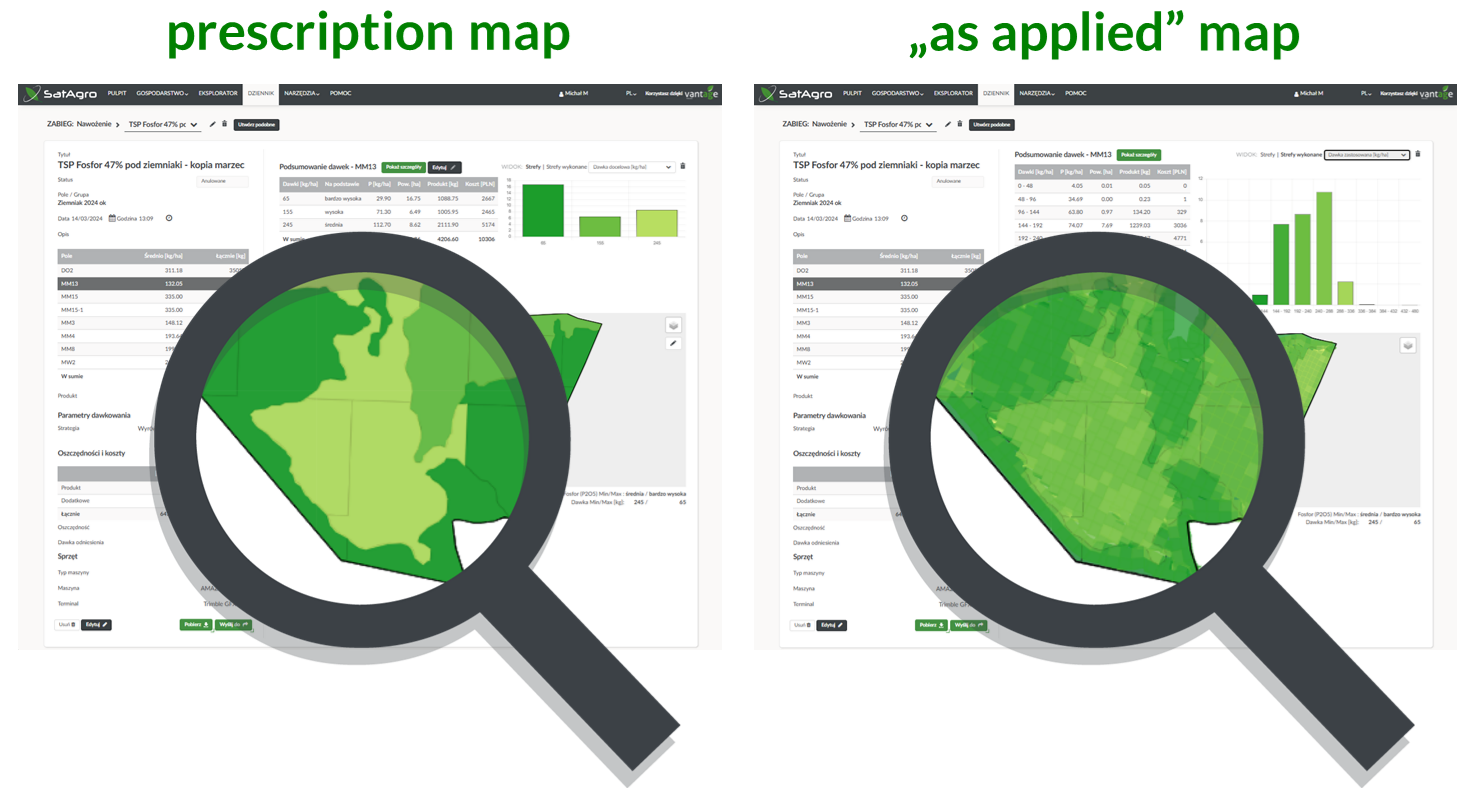

The second benefit is access to information on the actual consumption of production inputs at any location in the field. Application maps are never carried out one-to-one by spreaders, sprayers or seed drills, and fuel consumption very much depends on local working conditions. Without the as-applied maps provided by the machines, we would not know how the plans for the various treatments were actually carried out and how the costs develop in different parts of the crop field.

The third benefit arises from the special role of digital yield maps provided by harvester combines. They allow us to understand much better the second aspect of crop profitability, after costs: revenue, and its distribution across the crop field. Only the juxtaposition of cost (means of production) and revenue (yield) gives us a complete picture of the crop profitability at each location. In SatAgro, such an analysis is possible in the Profitability module, whereby, in the absence of a yield map, yield zones can be determined from satellite images.

The fourth benefit relates to improved documentation of the carbon footprint of the crop. Fertiliser and fuel often make up the vast majority of it. With machine reports, both of these components can be documented with a high degree of accuracy, and in map form. In addition, such a format is relatively more reliable, which should be helpful if the farm applies for funding for its decarbonisation efforts.

Hello SatAgro, this is the machine

At present, feedback to the SatAgro platform comes from terminals on machines of the AGCO Group (primarily Fendt and Valtra), John Deere, as well as machines equipped with terminals from Trimble or the Polish manufacturer Hydrasystem. In addition, communication is made possible by mobile applications. In the case of Amazone implements, data from the SatAgro app can be shared directly with the AmaTron Share app. In addition, FMS and machines from different manufacturers can ‘talk’ to each other thanks to stand-alone data exchange services such as agrirouter, which also works with SatAgro. The list of brands and machine types is open, if only because the inherent flexibility of the technology theoretically allows wireless communication to be easily established, for example by installing a mobile app on the machine terminal, as long as this environment is open to it.

Of course, we would ideally like to connect to all terminals and services on the market, but in any case this requires considerable effort. This is especially true given that the situation is very dynamic, as is the entire digital agriculture sector. It is often the case that a manufacturer’s data exchange technology changes several times during the course of our efforts to enable the communication. Fortunately, because we have full control over the SatAgro platform, we are able to technologically adapt to virtually any partner – it is just a matter of time and goodwill.

The challenges in farm digitalisation

In the context of the still unsatisfactory availability of the Internet, we believe that transferring data to and from machine terminals via a memory stick still makes sense, at least as an emergency option. Nevertheless, one has to admit that the idea of remotely receiving information from the machine is a hit. The automation of data collation and reports is necessary for the farm to make practical use of digital technologies in crop management. This complex process cannot be a challenging and time-consuming part of the machinery operator’s job.

Observing the current revolution in agriculture, one can make this general conclusion: integrate or perish. The value of our platform’s existence to the farm is directly proportional to the degree of our integration with other solutions around. The work we have done on communicating with the elements of the Agriculture 4.0 system has led us to step into the role of their integrator and coordinator. A farmer who can plan treatments in SatAgro, and successfully transfer application maps to all the precision machinery he owns, and can then collate information flowing from the machines, gains a powerful tool for coherent crop management above technological divides.

The busiest period of the annual cycle has just ended, with the majority of treatments completed, including fertiliser treatments and precision seeding. More and more farms have access to sprayers, spreaders and seeders compatible with Variable Rate Application technology. Unfortunately, there are still regular minor glitches in terms of data standards, out-of-date software, inactivated licenses and, of course, shortcomings on our side. The number of such problems seems to decrease from season to season, as the standards of machines and support from their manufacturers’ representatives, as well as the general level of knowledge on farms, improve. However, we regularly receive enquiries from more or less stressed farmers who cannot fire up a precision treatment. There are, of course, more of these the more systems we are able to communicate with. We always appeal to our users – test your technology well in advance of the actual treatments. Apart from creating a beautiful application map, there are several pieces of the jigsaw needed to put it into practice. Fortunately, once a puzzle is put together, it has the potential to work again and again.

Platform

Platform